Electric Actuator VALVES

Good Supplier, proudly presents you to the Electric Actuator.

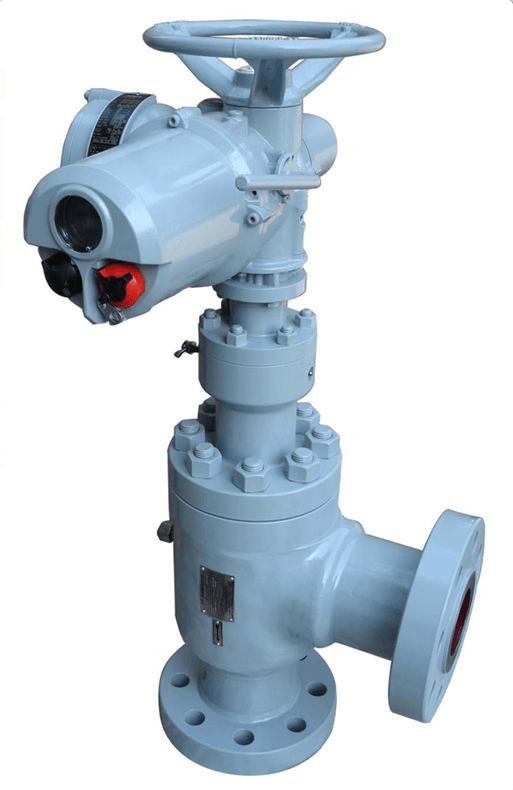

Electric valve is mainly composed of the valve and electric actuator two parts, electric installation using an electric actuator. Electric actuators are divided into two different types: rotary and linear.

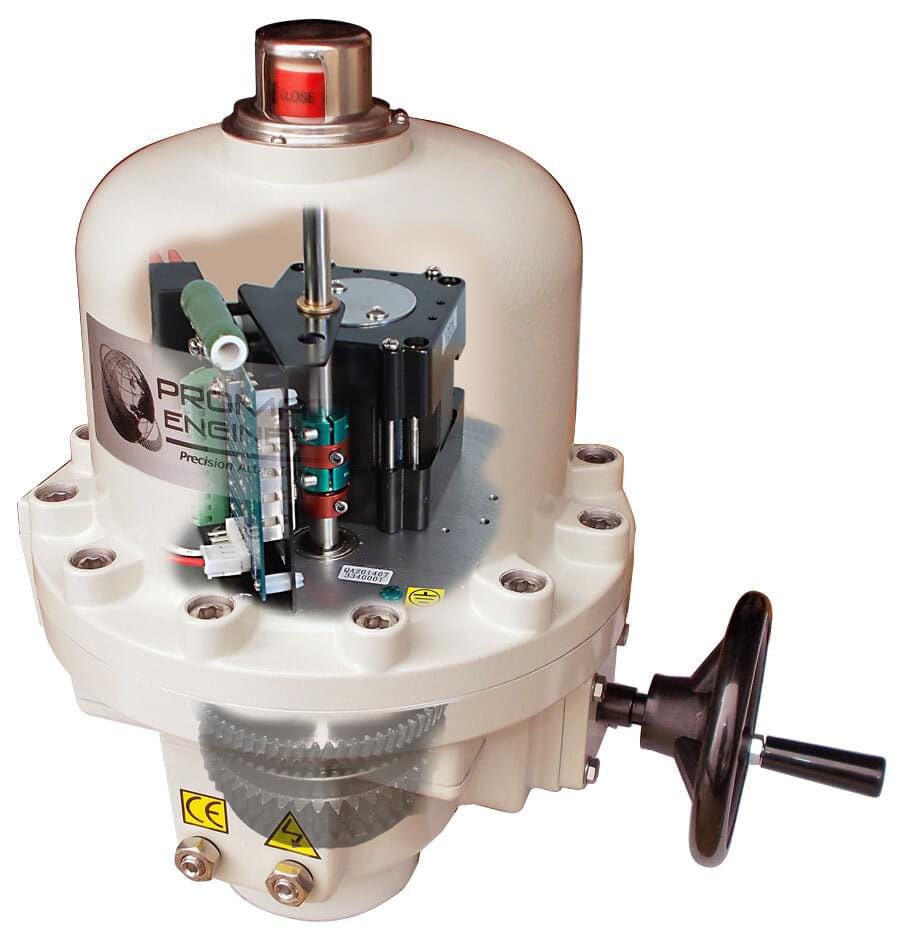

Rotary electric actuators rotate from open to close using butterfly, ball, and plug valves. With the use of rotary electric actuators, the electromagnetic power from the motor causes the components to rotate, allowing for numerous stops during each stroke. Either a circular shaft or a table can be used as the rotational element.

When selecting an electric rotary actuator, the actuator torque and range of motion should be considered. The actuator torque refers to the power that causes the rotation, while the full range of motion can be either nominal, quarter-turn, or multiturn.

Rotary electric actuators are used for modulating valves, which are divided based on the range from multi-turn to quarter turn.

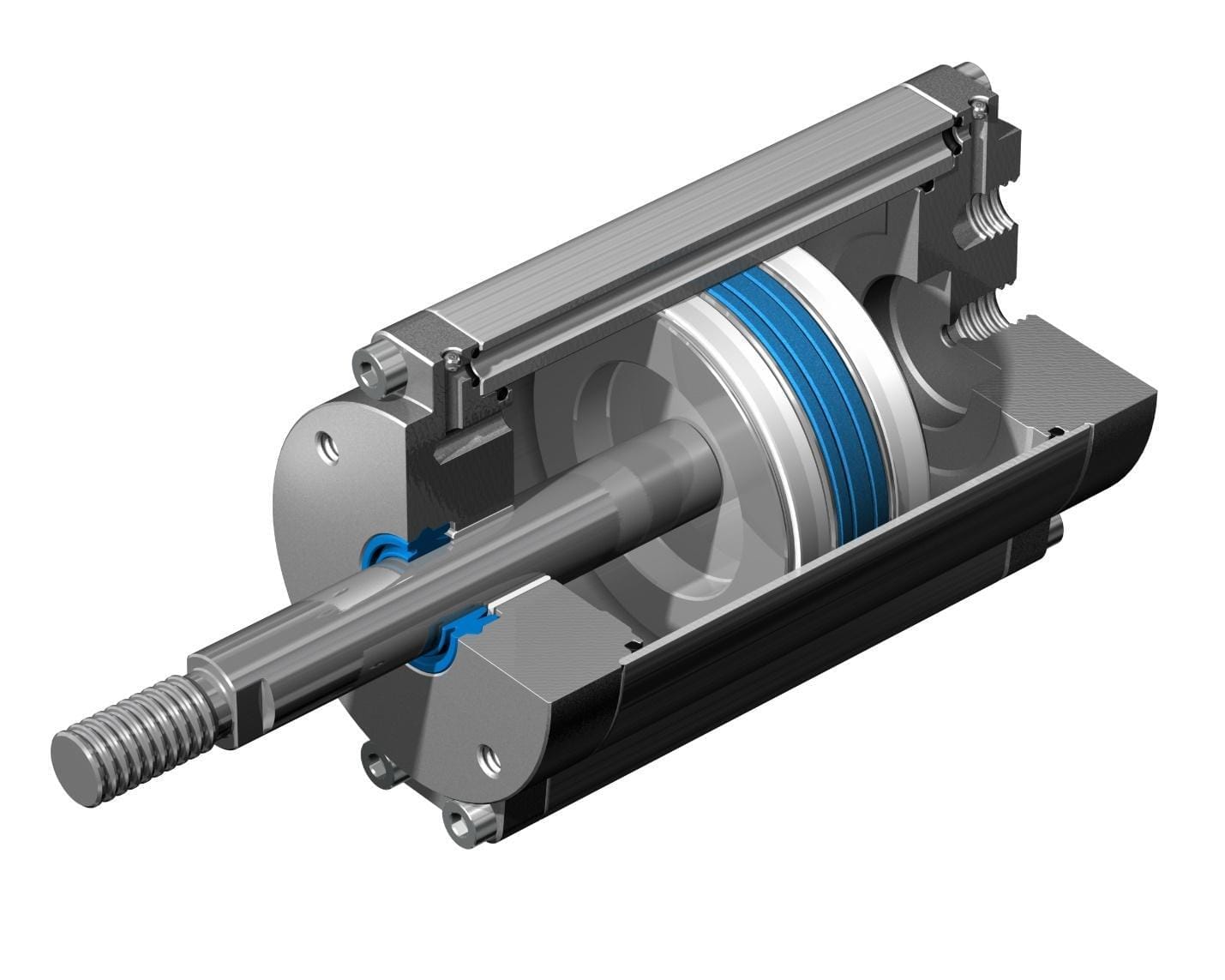

Electrically powered multi-turn actuators are one of the most commonly used and dependable configurations of actuators. A single or three-phase electric motor drives a combination of spurs and/or level gears, which in turn drive a stem nut.

The stem nut engages the stem of the valve to open or close it, frequently via an acme threaded shaft. Electric multi-turn actuators are capable of operating very large valves quickly.

product features

Industrial automation – By programming and adjusting the signal, the valve can be started or closed remotely by the system. Engineers do not need to be present to open the valve, reducing labor costs. When the engineering environment is worse, the engineer does not have to open the valve on the spot, and the safety of the engineer can be guaranteed.

At the same time, the electric valve can work for a long time up to 99 hours to achieve engineering automation, improve production efficiency, and speed up the construction of the project.

The Low Failure Rate – Electric actuator valve with load protection device. When the voltage is too high, or the working time is too long to cause the motor to overheat, the load protection will be turned on. But the motor temperature cooling, then only need to return on the power supply, can be opened again.

And because the motor drive mode opens and closes more smoothly, without the disadvantage of too much instantaneous impulse, the failure rate can be greatly reduced.

The Safe and Easy Installation – Electric actuator valve to motor-driven, easy to install, only with the factory’s original automatic control line can save installation costs.

Although the cost of an electric actuator valve is higher than the cost of a manual valve, the benefits of an electric actuator valve are several times of a manual valve.

An electric valve actuator serves no purpose on its own if there is no valve to operate. Thus, it is the valve that designates the type of electric actuator required.

Multiturn valves require multiple turns from the actuator to move the valve such as a gate valve.

Quarter-turn valves require a 90-degree turn from the actuator to move the valve such as a ball or butterfly valve.

Linear valves require a linear force from the actuator to move the valve such as a globe or diaphragm valve.

Get in contact with us NOW to have the best quality of good and reliable parts for the industrial valves in the industry!

The mechanism of electric actuators may vary from one type to the next but there are three basic components to its operation: an electrical signal, a power supply, and a moving mechanical shaft.

The motor of an electric actuator can operate on any voltage and is used across many different industries. The most common voltages used in single-phase motors are: 115 VAC, 24 VAC, 12 VDC, 24 VDC, 208 VAC, 230 VAC.

In addition to these options, three-phase motors also use voltages of 230 VAC and 460 VAC.

An actuator’s brake is mounted on top of the motor. It’s responsible for stopping the media from forcing the valve open when it should be closed by locking the motor rotor in position when not in use.