Steam Choke Valves

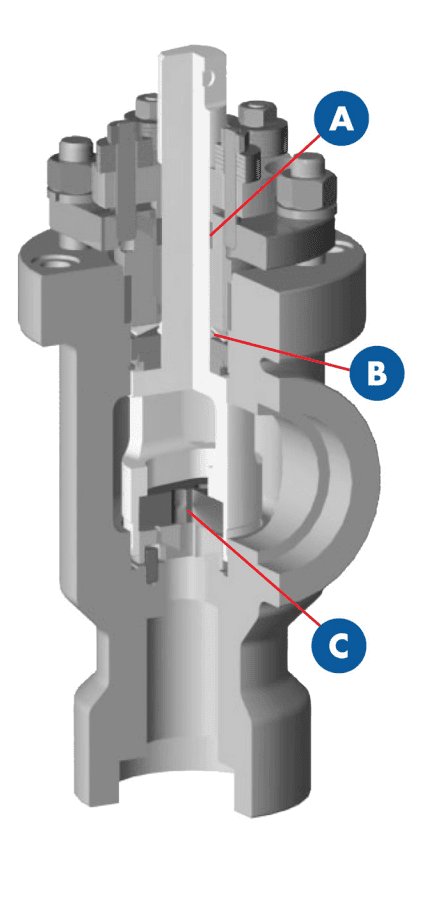

A – The stem/fork packing is isolated from the bonnet seal arrangement and is live-loaded. Belleville springs on the packing gland bolts self-adjust to maintain constant packing load regardless of thermal cycling. The design reduces the potential for packing leaks.

B – Belleville springs accommodate for thermal expansion of the choke’s internal components. During thermal cycling in startup or normal operation, the Belleville springs self-adjust to maintain an ideal contact load between the control discs.

This self-adjustment eliminates the possibility of lockup, regardless of process temperature or pressure (with the material limits). The internal springs also provide a constant load to prevent external leakage trough the bonnet packing.

C – The control discs are designed to provide precise control so that production rates are controlled with a high degree of accuracy. The discs also provide long-term erosion resistance in high-velocity, saturated steam service.

Various orifice shapes, size and configurations are available for a wide range of production rates and control requirements. The steam choke can easily be retrofitted with new discs if well conditions or production rates change over time.

Get in touch with us today and find out more about our products. We guarantee high quality!

Our steam choke is designed for the harsh conditions associated with steam injections. The rugged, maintenance-free steam choke features a self-adjusting, double live loaded design.

PRODUCT Features

- 2''Choke Body SW WCB

- DISC 2-1/4'' 17-4 H1150/QPQ

- DOWEL PIN. 188x5 ALLOY STEEL

- FORK 28 F/T 28, Y28 17-4 PH/QPQ CB7 Cu

- BOTTOM BEARING 410 S.S

- TOP BEARING 316 S.S

- 1-1/16'' 150-4500# BELLVILLE SPRING INC 718/HT

- BONNET 28F/T28, Y28 304 S.S

- ADAPTER 4130 HT

- STUD BONNET B8M

- NUT BONNET GR8M

- LOCKWASHER BONNET CS

- STUD GLAND B8M

- SPRING GLAND 302 S.S

- NUT GLAND GR8M

- 1500#MOUNTING BRAKET WC8

- SOCKET HEAD CAPSCREW, MOUNTING A574

- LOCKWASHER, MOUNTING CS

- RETAIN RING INTERNAL 302 S.S

- BOTTOM SEAL GRAFOIL

- GASKET BODY GRAFOIL/INCONEL

- PACKING BONNET 310 S.S/GRAFOIL

- PACKING GLAND 316 S.S/GRAFOIL

- SETSCREW A574